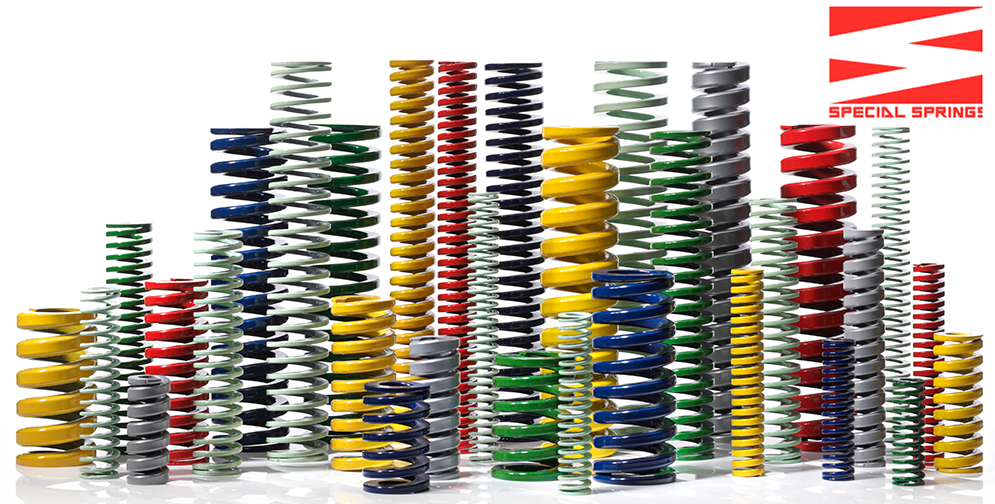

These mechanical springs are vital in manufacturing machinery, for applications such as stamping, forming, shearing and bending in industries including automotive, aerospace, white goods and many others. It is critical to maintain high quality standards.

By choosing a supplier with ISO 9001 accreditation, you will be buying from a distributor who puts quality management and customer satisfaction first. ISO 9001 is a globally recognised standard for quality management. With this focus on high performance quality, you can avoid expensive machine downtime, equipment failure and the associated operational risks.

Let’s take a deeper look, to learn the importance of ISO 9001 Quality Management Systems, and see how it affects the whole process from quality assurance to risk management.

Die springs are a precision component and require manufacture to precise specifications. In applications such as punching or stamping or use in injection moulds, the springs are under extreme stress. They are designed to withstand these stresses, however any deviation, however minor, from the specification can lead to the failure of the spring and costly downtime of the machinery.

From this, it can be seen that consistency in in manufacture is crucial, and the requirement is for reliable products that perform flawlessly in demanding environments. Conformation to ISO 9001 enforces a rigorous adhesion to quality control. Checks at every stage of the manufacturing process reduces the chances of defects and operational breakdowns.

ISO 9001 helps distributors maintain consistency by requiring a rigorous set of quality controls and checks at every stage of the distribution process. From receiving shipments from manufacturers to delivering them to end users, distributors can ensure that every die spring adheres to the specified standards, reducing the chances of defects and operational breakdowns.

Die springs are used in high pressure environments, and are exposed to huge pressure and so an unexpected failure can have catastrophic consequences. Ranging from machine downtime, through machine damage and potentially human injury. These issues must be assessed and proper measures used to mitigate issues before they occur as part of the implementation of ISO 9001. Risk management may take the form of close inspection of the springs on arrival in order to catch inconsistencies. A pro-active mindset to identifying potential issues is adopted, whether these issues are due to product defect, incorrect handling or even supply chain disruption.

ISO 9001 demands early detection of issues. By addressing potential risks early, the chance of product failure is addressed, therefore protecting the customer from expense and disruption.

This is an important factor to consider, especially for industries such as Aerospace, Automotive, Food and Beverage and Pharmaceutical, and in fact, many of these industries require this certification as a prerequisite before purchasing in order to comply with quality control regulations.

In the rare occurrence of a defect, it is crucial to be able to trace parts back to the point of origin to discover the cause of the issue, whether this be a faulty batch or a manufacturing issue. This allows any defective items to be quickly pinpointed and removed from the supply chain, and if required, product recalls or corrective measures to be implemented.

By adhering to ISO 9001, careful and comprehensive documentation is required at every step. This very traceability provides transparency - whether this is from supplier records to customer deliveries, there is accountability throughout the supply chain. ISO 9001 allows for the maintenance of accountability throughout the supply chain.

Participation in ISO 9001 encourages the regular review and improvement of business practices and processes. This focus on continuous improvement inspires an aim for better efficiency, higher quality products and excellent customer service. Performance is evaluated, and customer feedback is monitored to continually strive for improvement. In a competitive market, purchasing from a supplier with ISO 9001 certification ensures a product from the market leaders.

The ISO 9001’s focus on customer satisfaction means that meeting or exceeding your expectations is key to long-term success. By adhering to ISO 9001 standards, we follow established processes to deliver quality products on time, handle issues efficiently and in a timely manner, and continuously improve our services based on your needs. In this way, we can guarantee that our products meet or exceed these requirements, and in doing so create trust and confidence, building strong relations.

ISO 9001 also requires us to evaluate our suppliers, their performance and ability to meet demanding quality standards. We work closely with top performing suppliers and have a close relationship which has lasted many decades and this contributes to the reliability of the entire supply chain, reducing risks and ensuring a steady flow of quality die springs.

In the world of die springs, quality is everything and ISO 9001 is the key to managing and documenting that quality. From ensuring that every spring meets precise standards to managing supply chains efficiently, ISO 9001 offers a comprehensive framework that helps us consistently deliver you the best products. The certification enhances process control, minimizes risks, builds stronger relationships, fosters a culture of continuous improvement.

ISO 9001 is not just about meeting a standard—it’s about ensuring we maintain excellence of quality, reliability, and customer satisfaction in every aspect of our business, to meet and exceed your expectation and to make it easy for you to choose the best!