Everything You Need to Know About Handwheels

13 May 2025  Hazel Smeeth

Hazel Smeeth

Handwheels are a simple yet fundamental component in many mechanical systems, and when attached to a shaft or spindle they offer an easy yet effective means of manual control of movement and alignment of mechanisms.

What are the Different Types?

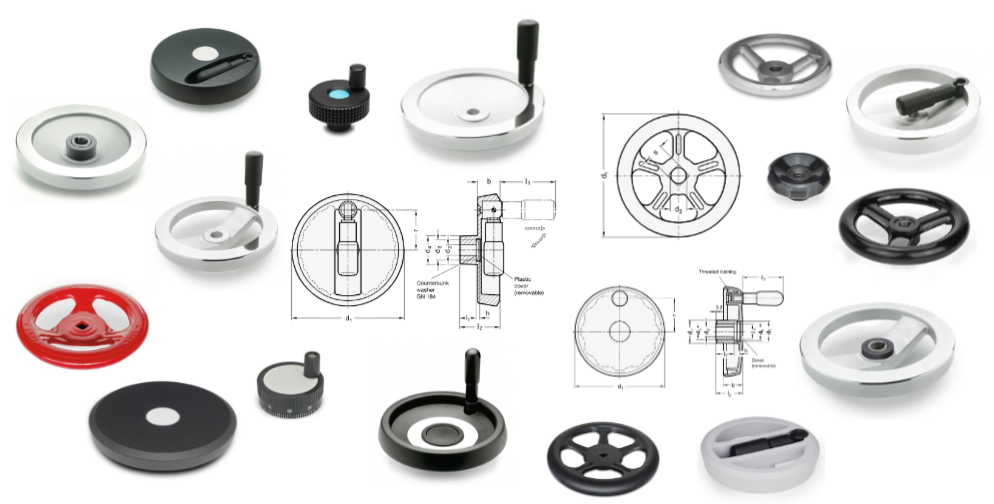

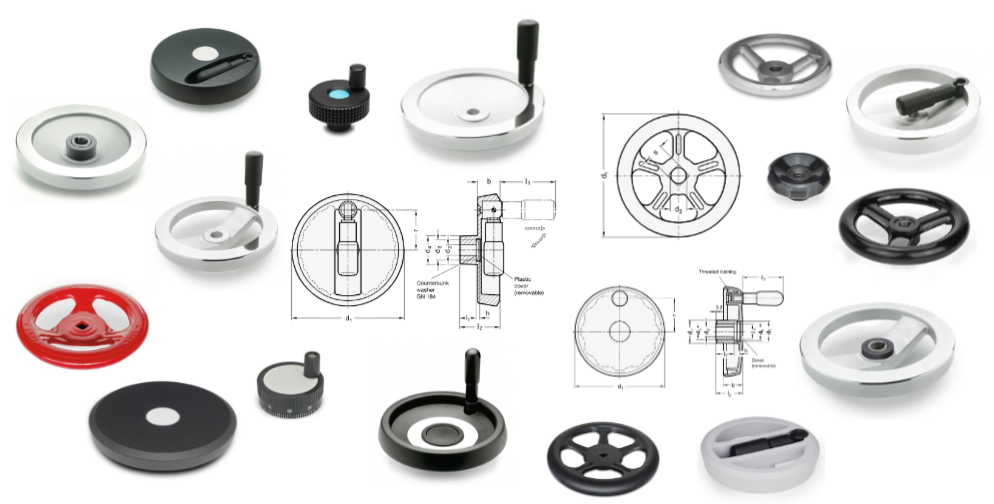

Spoked and solid handwheels may be used with an optional handle, and this may be fixed or revolving according to preference.

Spoked Handwheels – spoked handwheels offer a reduction in weight, and provide more gripping surfaces, making these handwheels an ergonomic, easy to handle choice. The open space also allows access to the area behind the handwheel, which may be crucial in some applications.

Solid or Disc Handwheels – these handwheels may offer a higher strength factor, especially where a heavy torque is required, as they are made from a single piece of material. This durability makes them perfect for heavy duty applications. They may incorporate knurled or moulded edges, to increase grip and ease of use. They are also useful in applications where preventing access to the fixings is a priority, for example where tampering may be an issue.

Retractable Handle Handwheels – these handwheels have a sprung handle, which retracts when it is not in use. Easy to access when required, this prevents handles from snagging in restricted spaces, or catching on clothing, for example, and therefore these handles have safety applications.

Safety Handwheels – these handwheels will rotate freely on the shaft, and in order to transfer rotation and torque, they must first be engaged by either pushing or pulling. This prevents unintentional use. When released, the handwheel is disengaged using spring force.

Control Handwheels – control handwheels are used for adjustment of controls using low torque. The handle is used for adjusting the setting, with the knurled edges then used for fine adjustment. Variants are available with a graduated scale, either of a standard design or customised to your specification.

Use of Keyways on Handwheels

Handwheels are available with a keyway in the bore. This allows the handwheel to be attached to a shaft in a fixed position, and prevents any slippage from occurring.

What Materials Are Used for Handwheels?

Common materials include a range of plastics, and metals such as aluminium, cast iron, steel and stainless steel. The selection is made depending on the application – plastic or aluminium could be chosen for lightness, cast iron or steel for strength or stainless steel for use in demanding environments.

What are the Applications for Handwheels?

Fluid and Gas Control Valves – Hand wheels are used on gate or globe valves, among others, where the handwheel is turned to activate or deactivate the flow of gasses and fluids. An example would be water to a fire extinguishing hose. For gated valves they offer a tight, secure seal, and on a globe valve, they provide precise control. Applications include:

- Chemical Processing, Oil, Petroleum and Gas Industries.

- Water Treatment.

- Power Generation using steam and other fluids.

- Waste Industries.

- Regulating the movement of rail cars in the Railway Industry.

- Marine Applications.

Positioning and Regulating – When used as a dial, handwheels allow precise and accurate position adjustment, regulate speeds and material flow and fine tune settings. Handwheels are ideal in:

- Machine Tool Positioning.

- Conveyor Systems.

- Material Handling Machinery.

- Packaging Equipment.

- Medical and Measuring Devices.

What are Their Advantages?

No power required – handwheels are operated manually, and because of this can be used in any situation.

Durability – their simple design and the use of robust materials contribute to a component that can withstand rigorous use and harsh conditions.

Precision – they are fully adjustable, allowing exactly the degree of opening you require.

Versatility – In order to meet every operational requirement, available in a range of designs and material.

Handwheels may be a traditional element, but their design has continued to evolve to keep pace with technology updates and they remain indispensable for their simplicity and their ability to provide precise manual adjustment. They are ubiquitous in industries ranging from manufacturing to transportation and remain a crucial tool in the operation of machinery and equipment.

View our full range here

Assembly Automation Conveyors Electronics Food & Beverage Industrial Machinery Machine Design Manufacturing Equipment Material Handing Mechanical Systems Medical Motion Control Power Transmission Precision Engineering

BERGER TOOLS LTD

BERGER TOOLS LTD